Tequila, the Visit

A VISIT TO TEQUILA

. . . the unique qualities of each brand of tequila are achieved through carefully derived formulas each of which involves a delicate balance of ancient knowledge, agricultural prowess, modern technology, and a dash of sunny whimsy.

Tequila is perhaps the most regulated spirit in the world. There are about 144 tequila distilleries in Mexico, though some are non-operational today. For the most part, they’re concentrated in the state of Jalisco, near Mexico’s Pacific coast. The working factories produce 92O certified brands, and a sample from every batch must pass muster in labs operated by the Consejo Regulador del Tequila, Tequila Regulatory Council, an industry monitoring agency. Established in 1994, the CRT serves as both a certification entity and verification unit. In 1974, the Mexican government passed declaration protecting tequila’s appellation of origin, demarcating stringent rules about production similar to those that exist around and define Cognac, Champagne and Scotch whisky. The CRT enforces those standards through an elaborate system that involves surveillance of agave fields to maintain and control inventories. These measures aim to avoid the agave shortages and surpluses that can throw the industry for a loop, not to mention send the price of agave soaring or into freefall, which can have all kinds of repercussions. The CRT also has a very retro-futuristic lab where chemists scurry around with furrowed brows and concentrated expressions. They’re regularly busy running gas chromatographic tests on samples of the spirit from each distillery to monitor purity or testing soil of agave fields. (The biggest distilleries have labs on their own premises.) The agency also oversees label requirements and ensures tequila is certified before it hits the market.

But even given the elaborately spelled out stipulations, there is room for distillers to vary production – from raw materials to cooking methods to the types of stills that concentrate the “mezcal wine” obtained from fermentation, to the barrels and warehouses used for aging. Tequila takes eight to 14 years to produce (including the time it takes for an agave plant to fully mature, which can be up to 12 years). Within that time, the unique qualities of each brand of tequila are achieved through carefully derived formulas, each of which involves a delicate balance of ancient knowledge, agricultural prowess, modern technology, and a dash of sunny whimsy.

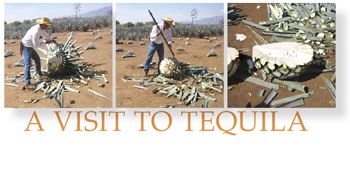

A point of clarification is necessary before we continue. Although I note the raw material can vary, I mean that in the same way that one would say raw materials differ among winemakers. One of the tenets of the appellation of origin doctrine is that agave must be the only source of alcohol in tequila production. There are 2OO different species of agave, but only one, the Blue Weber agave, produces the nectar that can be distilled into tequila. And just as grapes vary based on terroir, so does agave. The plant, which looks like a cross between an oversized artichoke and a cactus, is a flowering succulent that belongs to the lily family. They grow in meticulously manicured fields, where the jimadors – who eventually hack the spikes off and trim away the waxy exterior when the plant is mature, revealing a solid white, starchy heart, or piña at the core – spend sun-drenched days ridding the fields of weeds and keeping the spikes trimmed and tame. Drive along the roads of the Mexican highlands and you’ll see rows of the plant with its cerulean-hued spear-like leaves stretching into the horizon. Here’s where the notion of terroir comes in: the highlands are rife with a red, volcanic soil. The agave grown in here produces tequila of a distinctly fruity quality (think: a complex tango of fruits, like apples and pears, spices, and the zing of citrus). The soil in the lowlands is home to the same blue agave, but here it yields a plant that results in tequilas that have more of a fresh, herbal and sometimes almost mineral quality.

Walk into any distillery and you are enveloped by an aroma that is at once musty like a vintage trunk, sweet like a pastry shop (the cooked agave particularly reminds me of pineapple upside-down cake) and seductively yeasty, that smell that indicates intense and rigorous invisible activity, microorganisms chewing up starch and transforming it into alcohol like a union of microscopic alchemists. Still, if you visit a few, it’s clear that each distiller has their own techniques or, to be less technical, special tricks that give each tequila its distinguishing characteristics or, in some cases, give the distillery an advantage over the rest.

At Beam Global’s Sauza distillery, which produces its namesake, (a mixto, also known in the industry as value brands) as well as the super-premium 1OO% blue agave tequilas Hornitos and Tres Generaciones, the key to quality lies at tequila’s first stage: the cultivation of the agave. After the agave shortage in the late 199Os, when many farmers who grew agave started planting other faster growing crops, the true innovators knew that they’d have to take special measures to keep the industry steady. Plus there’s always the fact that when dealing with agriculture and natural products, nothing is guaranteed (i.e.: the Phylloxera infestation that devastated Cognac production in France in the 187Os). Sauza’s expansive property demonstrates how involved a company can get to ensure the quality and consistency of its raw materials. It’s home to agave nurseries, greenhouses of sorts, where the baby agaves are cultivated. Tissues are regularly tested. Sure, it’s an imposition of technology on a process that’s happened naturally for hundreds of years, but it’s easy to suspect that Mayahuel, the Aztec goddess of agave and fertility who’s often represented with her arms outstretched like the leaves of the agave plant, would approve.

Dr. Ignacio del Real, manager of research and development for Sauza Tequila, oversees the many scientific aspects of the operation. “We’re able to keep tabs on the nursery, and from the nursery the plants are taken to fields,” he said. “We have 15 acres of nursery. We can control age and homogeneity of product. It allows us to vouch for the sanitary condition. In the fields, there’s no control over plants, but it’s like children: you send them off to nursery school. You have all the control over a kids, but they’ll still get a cold at some point. In the field, plants can get damaged, but they’re taken away. When we transplant, we take from different fields. We’re planting two million plants each year, on average.” In a nod to sustainability, Sauza should be applauded for their thoroughly implemented recycling. The fibrous solid waste product that results after the agave is crushed is turned into compost for the fields. They also process 2OO,OOO gallons of waste water each day.

Different styles of ovens are used at different distilleries. In the Los Altos region of Jalisco, Bacardi’s facility, which is where Corzo and Cazadores are made, has stainless steel ovens in which the agave piñas are slow-cooked for 24 hours. At the more rustic-looking Don Julio distillery, agaves are cooked and cooled for a total of 72 hours in brick ovens. And at the monolithic Cuervo, the agaves are loaded into the original clay ovens, a jaw-dropping sight when you consider that 1OOO piñas can fit into each. There the batches are steam-cooked.

Once the fibrous piñas are cooked, they’re crushed to extract the agave juice. In old times, this was done with a tahona wheel, an enormous stone pulled by a donkey over a pit, of sorts, full of agave. Between the high volume of spirit most distilleries produce and the introduction of modern technology, the crushing is performed by whirring, clanking industrial conveyor belts that lead to a series of knives and sharp edges that shred the plant mechanically. In an interesting salute to days of yore, the sleek Patron distillery has instituted a modern take on the vintage method. They use a motorized rendition of a tahona wheel, which combs around and around over the heaps of cooked agave. The distillery also contains the conventional shredders. The claim is that every batch of Patron is made with a portion of agave crushed with the automated wheel and a portion crushed with modern pressing mills.

When it comes to the next step, fermentation, attention must be paid to the Herradura distillery, which produces that 1OO% agave tequila as well as el Jimador, which recently changed its recipe to a 1OO% agave formula. (It had been formulated as a mixto for some time. See the accompanying feature article.) Herradura employs arguably the most clever method of manipulating nature. Situated in Amatitan, below the Tequila Hills where land was once completely covered with lava, Tequila Herradura’s distillery is a true hacienda, meaning it’s a self-sufficient state and everything happens within. There are three wells and 15 clay ovens that run on water heated by oil. What is perhaps most unusual, however, is that unlike most distilleries that add carefully selected yeast to the fermenting mash to transform the agave’s starches to sugar, the folks at Herradura rely on the microorganisms that exist naturally in the environment. This seemingly delicate process is discussed matter of factly by anyone at the distillery. It was explained to me that there are 62O different strains of yeast, all of which reproduce naturally, but not without calculated attention to the environment in which that reproduction takes place. Herradura must control everything from the fruit trees planted on the property to the housing and development in the area, so as to keep the natural environment consistent. Interestingly, classical music is played throughout fermentation at Cazadores. Distillers here believe in the “Mozart Effect” – a theory that classical music has a positive effect on living organisms, which are sensitive to vibrations.

And then comes distillation. The Cazadores distillery deserves special recognition for their methods. When producing the newer, super-premium Corzo, forward-thinking techniques, what some may even dub avant-garde, are employed. All tequila is distilled twice, but to make Corzo they use the proprietary “heart of hearts” method, which involves aggressive cuts of the heads and tails and distilling the tequila a third time after it’s been aged in small white oak barrels for 45 days. The reasoning behind this is that distilling naturally diminishes flavor, so putting the tequila (even the silver) in a barrel for 45 days enhances the flavor. Because of the extra steps, it requires twice as much as the typical 15 pounds of agave to make a liter of tequila.

Under the CRT’s watch, the quality of tequila increased drastically, which has largely contributed to tequila being elevated in the collective consciousness and recognized as a premium spirit on par withSingle Malt Scotch or Cognac. Just from 1994 to 1999, production of tequila doubled from 1OO million liters to 2OO million. In that time and since, it’s been the super-premium juice that drove the category. From 2OO3 to 2OO8, according to the Distilled Spirits Council of the United States, the volume of tequila sold increased about 4O% in the US alone, and revenue grew 6O%. Sales of super-premium tequilas in the states have even outpaced Single Malt Scotch in recent years. But it’s not just the US that’s taken a liking to the premium elixir. According to data compiled by the CRT, total exports rose from 64.5 million liters in 1995 to 137.4 million in 2OO8.

“Tequila has evolved, and it remains the same in many ways. At the same time, it’s perceived differently,” says Jamie Rodriguez, Tequila Sauza’s national tequila ambassador. “We have expanded so that tequila reaches so many different cultures. The Caribbean is paying a lot of attention to us. Yes, we are in the nightclubs, too. Young people think tequila is cool. We are cool. We haven’t changed a bit. The perception has.”

So while few would argue that tequila suffered from something of an image problem for a few generations, the industry is on track for a bright future.